- Ergonomic driver seat for perfect all-round visibility

- Clear information display

- Excellent hill climbing ability via self-locking differential

- 3-point swivel joint for optimum driving comfort

- Hydrostatic steering

- Optimum ease of maintenance, long service intervals

EQUIPMENT

2 armrests, 3-point articulation, Adjustable scraper, Dashboard with displays, indicator lights and switches, Automatic traction control and anti-slip control, Battery isolation switch, Control console with steering column adjustment, Operator’s platform with entry from both sides, Speed preselect, Hydrostatic steering, Vibration-isolated operator’s platform, Stepless hydrostatic all-wheel drive, Handrails on the operator’s platform, Dozer blade.

OPTIONAL EQUIPMENT

Working lights, Back-up alarm (reversing), Frequency display, vibration, Speedometer, HAMM Compaction Meter, Radio, ROPS, rigid, Rotating beacon, Hydraulic hose protection on front frame, Protective roof, Padfoot shells, Automatic vibration system, Version with additional fuel prefilter, Auxiliary heater, ROPS cabin, ROPS cabin with heating, ROPS cabin with heating and air conditioning, Rear area camera, HCQ Navigator, Telematics interface, Protective grille for lighting package.

- Ergonomic driver seat for perfect all-round visibility

- Clear information display

- Excellent hill climbing ability via self-locking differential

- 3-point swivel joint for optimum driving comfort

- Hydrostatic steering

- Optimum ease of maintenance, long service intervals

EQUIPMENT

2 armrests, 3-point articulation, Adjustable scraper, Dashboard with displays, indicator lights and switches, Automatic traction control and anti-slip control, Battery isolation switch, Control console with steering column adjustment, Operator’s platform with entry from both sides, Speed preselect, Hydrostatic steering, Vibration-isolated operator’s platform, Stepless hydrostatic all-wheel drive, Handrails on the operator’s platform, Dozer blade.

OPTIONAL EQUIPMENT

Working lights, Back-up alarm (reversing), Frequency display, vibration, Speedometer, HAMM Compaction Meter, Radio, ROPS, rigid, Rotating beacon, Hydraulic hose protection on front frame, Protective roof, Padfoot shells, Automatic vibration system, Version with additional fuel prefilter, Auxiliary heater, ROPS cabin, ROPS cabin with heating, ROPS cabin with heating and air conditioning, Rear area camera, HCQ Navigator, Telematics interface, Protective grille for lighting package.

- Ergonomic driver seat for perfect all-round visibility

- Clear information display

- Excellent hill climbing ability via self-locking differential

- 3-point swivel joint for optimum driving comfort

- Hydrostatic steering

- Optimum ease of maintenance, long service intervals

EQUIPMENT

2 armrests, 3-point articulation, Adjustable scraper, Dashboard with displays, indicator lights and switches, Automatic traction control and anti-slip control, Battery isolation switch, Control console with steering column adjustment, Operator’s platform with entry from both sides, Speed preselect, Hydrostatic steering, Vibration-isolated operator’s platform, Stepless hydrostatic allwheel drive, Handrails on the operator’s platform, Dozer blade.

OPTIONAL EQUIPMENT

Working lights, Back-up alarm (reversing), Frequency display, vibration, Speedometer, HAMM Compaction Meter, Radio, ROPS, rigid, Rotating beacon, Protective roof, Padfoot shells, Automatic vibration system, Hose protection, Version with additional fuel prefilter, Auxiliary heater, ROPS cabin, ROPS cabin with heating, ROPS cabin with heating and air conditioning, Rear area camera, HCQ Navigator, Telematics interface, Protective grille for lighting package.

3-point articulation for outstanding traction and off-road mobility

Simple, intuitive and language-neutral operation

Ergonomic driver platform with rotatable seat operating unit, adjustable driver’s seat and tilting steering column

Excellent view of the machine and the construction site

High compaction performance thanks to high line load and big amplitudes

EQUIPMENT

2 armrests, 3-point articulation, Adjustable scraper, Dashboard with displays, indicator lights and switches, Automatic traction control and anti-slip control, Battery isolation switch, Control console with steering column adjustment, Operator’s platform with entry from both sides, Speed preselect, Hydrostatic steering, Vibration-isolated operator’s platform, Stepless hydrostatic allwheel drive, Handrails on the operator’s platform, Dozer blade.

OPTIONAL EQUIPMENT

ROPS, rigid, Auxiliary heater, Radio, Protective roof, Version with additional fuel prefilter, HAMM Compaction Meter (HCM), Speedometer, Frequency display, vibration, Back-up alarm (reversing), Automatic vibration system, Working lights, Rotating beacon, Protective grille for lighting package, Hose protection.

Ergonomic driver seat for perfect all-round visibility

Clear information display

Excellent hill climbing ability via self-locking differential

3-point swivel joint for optimum driving comfort

Hydrostatic steering

Optimum ease of maintenance, long service intervals

EQUIPMENT

2 armrests, 3-point articulation, Adjustable scraper, Dashboard with displays, indicator lights and switches, Automatic traction control and anti-slip control, Battery isolation switch, Control console with steering column adjustment, Operator’s platform with entry from both sides, Speed preselect, Hydrostatic steering, Vibration-isolated operator’s platform, Stepless hydrostatic allwheel drive, Dozer blade, Handrails on the operator’s platform.

OPTIONAL EQUIPMENT

Protective grille for lighting package, Rotating beacon, Protective roof, Padfoot shells, Automatic vibration system, Auxiliary heater, Hose protection, Version with additional fuel prefilter, HCQ Navigator, , ROPS cabin, ROPS cabin with heating, ROPS cabin with heating and air conditioning, Working lights, Backup alarm (reversing), Frequency display, vibration, Speedometer, , Radio, ROPS, rigid, Telematics interface.

- 3-point articulation for outstanding traction and off-road mobility

- Simple, intuitive and language-neutral operation

- Ergonomic driver platform with rotatable seat operating unit, adjustable driver’s seat and tilting steering column

- Excellent view of the machine and the construction site

- High compaction performance thanks to high line load and big amplitudes

EQUIPMENT

2 armrests, 3-point articulation, Adjustable scraper, Dashboard with displays, indicator lights and switches, Automatic traction control and anti-slip control, Battery isolation switch, Control console with steering column adjustment, Operator’s platform with entry from both sides, Speed preselect, Hydrostatic steering, Vibration-isolated operator’s platform, Stepless hydrostatic allwheel drive, Dozer blade, Handrails on the operator’s platform.

OPTIONAL EQUIPMENT

Protective grille for lighting package, Rotating beacon, Protective roof, Automatic vibration system, Auxiliary heater, Hose protection, Version with additional fuel prefilter, ROPS cabin, Working lights, Back-up alarm (reversing), Frequency display, vibration, Speedometer, HAMM Compaction Meter (HCM), Radio, ROPS, rigid, Telematics interface.

Mastering every slope

Ingenious power train concept provides a climbing ability in excess of 60%

The compactors of the Series 3000 are true classics for earth work because they combine modern design with proven engineering. They put their capabilities to the test day in, day out, in every corner of the world. One of their outstanding features is their climbing ability. Depending on the model and configuration, they can scale inclines of 60% or more, compacting extremely efficiently as they go.

On the compactors equipped with Hammtronic, the load-dependent speed control protects the engine and reduces fuel consumption.

The 3-point articulation ensures uniform weight distribution between the front and rear sections and thus outstanding traction even in rough terrain.

On the models equipped with Hammtronic, the anti-slip control and continuously variable hydraulic motors ensure optimum traction force at all times

- Unobstructed view to the rear with no intrusive exhaust pipe.

- The cabin can be supplied with or without air conditioning.

- Unobstructed view of the drum.

- Continuously adjustable steering column.

- Comfortable driver’s seat, individually adjustable for height and weight.

The Series 3000 offers ergonomically optimised workspaces as standard. They allow roller drivers to work with total concentration for many hours at a stretch

Perfect overview

Ergonomically optimised and comfortable

The Series 3000 compactors offer operators plenty of space because every model has a large cabin or operator’s platform, accessible from either side. Another practical and comfortable feature is the spring-mounted, height-adjustable driver’s seat. It can be turned, moved to either side, and also moved forwards and backwards on most models. The rake of the steering column with the dashboard is also continuously adjustable to match. Here, every driver is sure to find his ideal working position.

Outstanding visibility

In addition, there is superb all-round visibility because the cabin and doors are fully glazed. This gives the driver a clear view of the drum at all times. The tyres and the space behind the roller are also fully visible because the engine hood has a slimline, sloping shape and the exhaust pipe is positioned so as not to interfere with the all-round view

Plenty of power

Great compaction performance

The 3000 series compactors bring enormous compaction force to the construction site. Their static linear load is every bit as impressive as their centrifugal force. In combination with Hammtronic, this power is put to particularly efficient use.

Not forgetting that the compactors can even master slopes of over 60% effortlessly thanks to Hammtronic.

Optimise consumption and power with Hammtronic

The Hammtronic electronic machine management system monitors all engine and vehicle functions and adapts the traction and vibration/oscillation drives as well as engine speed automatically to the prevailing operating conditions.

Accordingly, all other components are operated in the optimum range. This significantly reduces fuel consumption as well as exhaust and noise emissions, enabling the compactors to operate in an especially environment-friendly, economic and efficient manner.

Higher quality with Hammtronic

On all compactors equipped with Hammtronic, the driver can preselect the desired speed. It automatically remains constant, as though under cruise control. This creates the optimum conditions for homogenous compaction. Continuously variable frequency control is also possible, enabling extremely precise adjustment of the compaction parameters. Last but not least, Hammtronic ensures gentle braking and acceleration of the machines – a further quality factor.

The HAMM 3-point articulation is the key to an exceptionally favourable weight distribution, enormous driving stability and supreme traction.

Optimum handling characteristics

The benefits of the 3-point articulation can be seen every day in many situations on the construction site. One plus factor is the exceptionally favourable weight distribution. It makes for enormous driving stability and ensures outstanding traction, even in rough terrain.

Another aspect becomes apparent when compacting uneven ground. Here, the articulated joint guarantees unrivalled driving comfort because it absorbs shocks extremely effectively. In addition, any tendency of tipping in curves is greatly reduced – an important safety factor. And last but not least, the 3-point articulation enables outstanding directional stability.

- CABIN – ROPS cabin with perfect all-round visibility. Outstanding view of the machine and surrounding construction site from the driver’s seat. 12 V socket, storage compartments, drinks holder and stacker as standard. Air conditioning and/or auxiliary heater available as optional extras.

- ROPS – Option. ROPS available for all machines, with or without protective roof according to preference

- REAR-VIEW CAMERA – Option. Camera with display on the operator’s platform for easier monitoring of the area behind the machine

- EASE OF OPERATION – Comfortable driver’s seat, individually adjustable and swivelling. Adjustable armrests. Height-adjustable backrest. Steering column individually adjustable.

- LIGHTING – Bright working lights, main headlights with LED or halogen lamps, depending on the model.

- 3-POINT ARTICULATION – Outstanding off-road mobility, absorbs shocks. Unrivalled driving stability, high resistance to tipping and top-class directional stability make for safe manoeuvring even on rough terrain.

- DRIVE CONTROL – Drive control with one or two joysticks, depending on the model. If equipped with Hammtronic, preselection of maximum speed and automatic support when reversing are included.

- ENGINE TECHNOLOGY – Robust, water-cooled 4 or 6-cylinder engines. Comply with the requirements of EU Stage II / EPA Tier 2 or EU Stage IIIA / EPA Tier 3, depending on the model version. Optional fuel pre-filter available.

- HAMMTRONIC – Option. Electronic machine management system for monitoring of all engine and vehicle functions. Automatic adjustment of traction and vibration/oscillation drives and engine speed to the prevailing operating conditions.

- WIDE RANGE OF DRUMS – Available with smooth drum or padfoot drum with vibration. Three-section split padfoot segments also available. Some models also available with VIO drum (vibration or oscillation).

- DOZER BLADE – Option. Available for selected models with smooth or padfoot drums.

- HAMM COMPACTION METER (HCM) – Option. Compaction meter, measures the rigidity of the ground in order to monitor compaction.

- HCQ NAVIGATOR – Option. System for comprehensive compaction control and documentation.

- TYRES – Come as standard with universal tread profile for machines with smooth drum or with tractor profile for machines with padfoot drum. Earth Mover tyres (EM profile) available as an option.

SIMPLE MAINTENANCE AND SERVICING

All daily maintenance items are located in readily accessible positions on the same side of the machine – the most important prerequisite for fast checks.

VISIBILITY

Safety and high compaction quality thanks to the outstanding overview of the machine and surrounding construction site from any sitting position.

ROBUST ENGINEERING

The intelligent design has proved its worth for many years all over the world and stands out for its robust execution.

3-POINT ARTICULATION

Ensures optimum driving comfort as well as outstanding traction and off-road mobility, absorbs shocks and enables safe manoeuvring, even on rough terrain.

GRADE ABILITY

The clever drive concept allows a great climbing ability, especially with the rollers Hammtronic.

Operation? It couldn’t be easier!

Clear cockpit overview

In terms of operation, drivers of Series 3000 compactors have it really easy: everything is clearly laid-out and self-explanatory.

Drive control is via one or two drive levers, depending on the model. The activation switch for the vibration is also located on the drive lever, so that the two most frequently used functions can be controlled with one hand.

The dashboard is notable for its unambiguous, internationally understandable marking and labelling. Here, HAMM has dispensed with language, using clear imagery instead. As a result, these compactors can be operated entirely without language skills and yet always with comprehensive information on the current operating status of the machine – an important prerequisite for high-quality ground compaction.

HCQ – HAMM Compaction Quality

HCQ: smart system for maximum compaction quality

High-quality compaction means compacting the ground to the required load-bearing capacity – over the entire area and to the required depth. HAMM has developed various measurement systems to check the compaction and bundled them under the name HCQ. These products aid the measurement, documentation and analysis of the compaction processes and offer the maximum possible flexibility, because they are modular in design and perfectly matched to one another

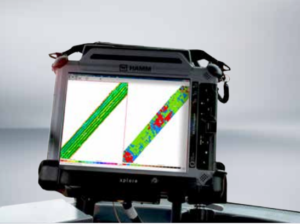

The HCQ Navigator’s mobile panel PC for the display and storage of all measurement data.

HAMM Compaction Meter: measuring subsoil rigidity in real time

The HAMM Compaction Meter (HCM) serves to measure and display the subsoil rigidity. To do so, an acceleration sensor on the drum measures the ground rigidity during dynamic compaction. The measurement result, the HMV value, shows the driver whether or not the subsoil is sufficiently compacted. In many cases, this information helps to reduce the number of passes and avoid over-compaction.

HCQ Navigator: all-over, homogenous compaction

The HCQ Navigator is a satellite-based documentation system for the collection and display of all important parameters during compaction. It creates a real-time compaction map via the HCQ satellite receiver. It shows the areas that have already been adequately compacted and those that require further compaction on a panel PC in the roller. The data from a number of rollers may also be linked via a WLAN. This enables the roller drivers to compact even more efficiently

HAMM has also provided for efficient maintenance of the rollers because all maintenance items are located on the same side of the machine.

For a long machine life

Efficient and economical

Robust 4 or 6-cylinder Deutz diesel engines in the Series 3000 compactors provide ample power with which to drive all components. At the same time, they have adequate reserves for efficient compaction, even under extreme conditions. They comply with the EU Stage II / EPA Tier 2 or EU Stage IIIA / EPA Tier 3 requirements – that means low exhaust emissions and low fuel consumption. Intelligent airflow enables the rollers to be operated even in high ambient temperatures. A supplementary fuel filter can also be installed. It eliminates excess water from the diesel fuel, ensuring reliable operation.

Quickly done: daily maintenance

The few maintenance tasks on the Series 3000 compactors are quickly done because the wellilluminated engine compartment is very low, making it readily accessible for the workshop technicians. The engine hood provides another benefit: thanks to the cleverly selected position of the pivot point, it can be opened wide, even in restricted headroom situations. Moreover, all maintenance items and the battery are easily accessible on one side of the machine

Solutions for value retention

HAMM offers various modules for intelligent maintenance. The most important solutions:

WIDIAG

WIDIAG enables WIRTGEN GROUP service technicians to read out the roller’s data log on the construction site. In the event of a fault, this speeds up the diagnosis because WIDIAG supplies valuable pointers to the source of the trouble.

WIDOS

WIDOS covers the complete spare parts catalogue, all instructions, hydraulic, electrical and hose system plans, machine data and documentation, safety instructions, component pictures and service documentation in numerous languages – on paper or CD.

WITOS

WITOS is the WIRTGEN GROUP’s intelligent telematics system for efficient fleet and service management. A SIM card allows the machine data to be transmitted automatically to the WIRTGEN GROUP service professionals. They determine the optimum time for the necessary maintenance work and deal with the upcoming tasks. In this way, the residual value, availability and performance of the HAMM rollers will be kept at a high level for a long time.

Flexible earth work professionals

Universally employable in earth work

With well over 30 different models, the Series 3000 covers the entire spectrum of medium and heavyweight compactors. It also includes various smooth and padfoot drums as well as different compaction systems. This makes the Series 3000 compactors universally employable – for example in roadbed compaction, earth work or building construction, building embankments and slopes and for compaction during cold recycling or soil stabilisation.

- Working lights with LED or halogen spotlights.

- The Series 3000 compactors are available with ROPS, cabin, protective roof or completely open.

- Available with vibrating or VIO drum (operates with vibration or oscillation), depending on the model.